Although it has been with us for over 30 years, Rapid Prototyping has been getting frequent mentions by technology correspondents in print and online as they report on the recent advances in 3D printing technology, which the Rapid Prototyping industry has been quick to adopt.

In this article, we’ll take a look a little more in depth at what Rapid Prototyping is and the benefits that it brings to the manufacturing industry.

So without further ado let’s delve into the world of Rapid Prototyping.

Rapid Prototyping – a multi-discipline technology.

Rapid Prototyping is actually the implementation of a number of techniques that lead to the manufacture of a scale model of a component or the complete product assembly. The process usually begins with a computer model of the product being made from geometric points and dimensions. This is known as Computer Aided Design (CAD)

The data from the CAD software is often pre-processed into a set of machine instructions before being transmitted to a device such as a 3D printer for production. This two stage process, design and pre-processing is known as CAD-CAM – Computer Aided Design – Computer Aided Manufacture.

The production of the design is usually handled by a 3D printer or a CNC device or by a process calledSterolithography

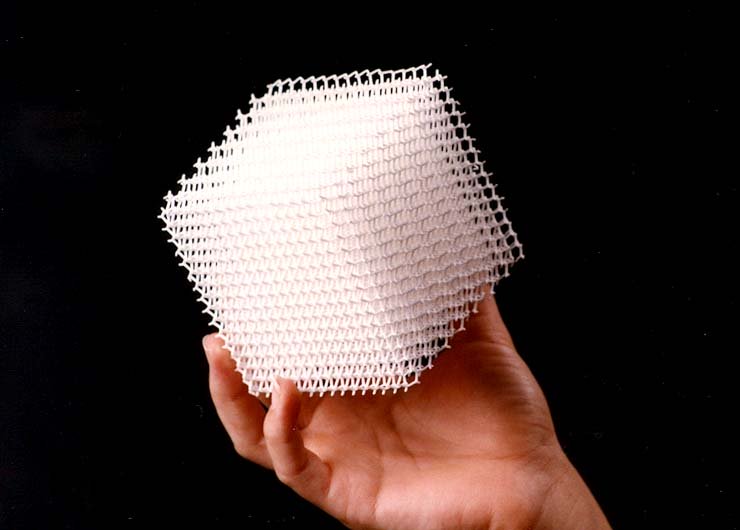

3D printers use an ‘additive later manufacturing; process to build a component. The part is made by layering very thin layers of plastic on top of each other. It may take many hours to make a part.

A CNC device is a machine that uses tools like saws and drills to create the desired component or assembly. CNC devices usually use a ‘subtractive method’, that is to say, a larger piece of the raw material is cut down to the size and shape required by the design.

Stereolithography is a process where a laser is used to set a special photosensitive resin. As the laser passes over the liquid resin, it solidifies. The laser passes over the resin many times to build up the cross section of the design. Each layer of the cross section sinks beneath the surface of the liquid resin. Eventually, the complete design will sit beneath the surface of the resin, which is then drained away.

It is worth noting that in Rapid Prototyping, the prototype component or assembly may be made of a different material to that which would be used when the product goes into mass production.

So how does Rapid Prototyping help product manufacture?

Getting an idea for a product from its first concept to mass manufactured item involves many stages. One of those stages is usually a cycle of prototyping where scale or actual size models are made. This can help to aid visualisation of the product, improve the design, plan for its eventual real assembly and manufacture amongst many other things. It is quite common to have a number of cycles of prototyping before the product is made on a commercial scale.

We spoke to Prototype Projects (http://www.prototypeprojects.com/) , one of the UK’s leading Rapid Prototyping businesses about the benefits their Rapid Prototyping services offer to their clients. They told us “Rapid Prototyping helps our clients keep their Research and Development costs down to a minimum as well as their progressing their projects in a timely manner. The costs for other small volume manufacturing methods are very much higher and the turnaround is often much slower”.

Rapid Prototyping in action

So now we know what Rapid Prototyping is and how it can benefit industry, we couldn’t resist using some videos that showcase just what can be made by 3D Printers, CNC and Stereolithography Machines. See if you can identify which method is being used during the video from JD Rock below

<iframe width=”853″ height=”480″ src=”https://www.youtube.com/embed/-LOGF3hFxHU” frameborder=”0″ allowfullscreen></iframe>

We hope that you’ve found our article on Rapid Prototyping interesting and informative. If you have any experience of Rapid Prototyping or are lucky enough to own a 3D printer (they are starting to emerge into the home market now), please share your experience in a comment here on our blog. Thanks for reading.